VeeaONE Edge Platform

- Self-forming, self-healing mesh for secure IP networking and local app hosting.

- Zero-touch onboarding for IP cameras and IoT sensors.

- Micro-segmented policies enforced on device.

At MWC 2026 Barcelona, we'll be introducing two transformational platforms purpose-built for operators entering the AI-native era.

Join Us

The construction industry faces daily challenges that stem from safety incidents, compliance lapses, equipment loss, and inefficiencies that collectively erode margins and put both people and projects at risk.

Veea Smart Construction brings real-time safety, compliance, and asset intelligence directly to the jobsite. Running on VeeaONE™ with MetaLynx™, all processing happens locally at the edge — delivering alerts in under 50 milliseconds, even without reliable internet. The result: safer workers, higher asset utilization, and streamlined operations without cloud dependency.

Veea's Smart Construction platform is bringing together edge networking, AI computer vision, policy enforcement, real-time location services, and seamless integrations into a unified system. Designed specifically for dynamic and high-risk jobsite environments, these capabilities provide real-time intelligence, stronger compliance, and scalable performance while minimizing cloud dependency, preserving data privacy, and reducing operational risk.

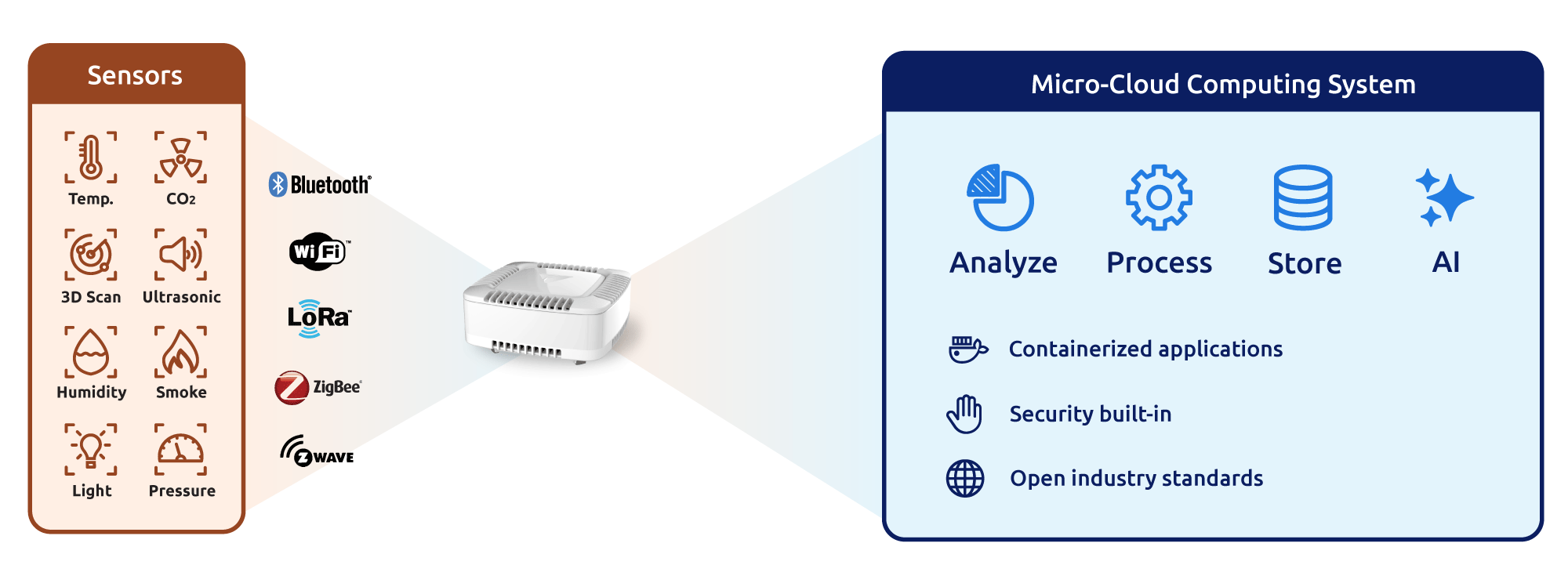

Smart Construction begins with data captured at the edge. A wide variety of sensors—ranging from temperature, humidity, and smoke detection to 3D scanning, ultrasonic, and pressure monitoring—connect seamlessly over Bluetooth, Wi-Fi, LoRa, ZigBee, and Z-Wave. All of this input flows into Veea’s micro-cloud computing system, where it is analyzed, processed, and stored locally with AI models running on-site. By combining containerized applications, built-in security, and open industry standards, the system delivers immediate, reliable intelligence without relying on external cloud services.

Together, these capabilities create a resilient, self-sufficient edge environment where jobsites gain actionable intelligence in real time. Sensor data is not only collected but contextualized: translating environmental changes, safety events, or equipment anomalies into instant alerts and automated workflows. With applications containerized at the edge, updates and new capabilities can be deployed rapidly without disruption, while the built-in security framework ensures that every data stream remains protected. This architecture allows construction teams to operate with confidence, knowing that critical insights, compliance checks, and operational controls are available on-site, even in low-connectivity or air-gapped conditions.

Traditional cloud-first approaches to AI introduce latency, increase backhaul costs, and create operational fragility in environments where connectivity is intermittent or non-existent. Veea’s edge-native architecture eliminates these weaknesses by ensuring that event detection, analysis, and alerting are all executed locally. This enables sub-50 millisecond response times, uninterrupted operation even in air-gapped conditions, and a more predictable cost structure with minimal reliance on costly bandwidth. The result is a platform that ensures resilience in the most demanding jobsite conditions while still allowing optional cloud backhaul for cross-site reporting, orchestration, or long-term data retention when desired.

| On-Site (Veea MetaLynx) | Cloud-Based Solutions | |

|---|---|---|

| Alert latency | Sub-50ms | Seconds to minutes |

| Works without Internet |

|

|

| Data stays local |

|

|

| Backhaul cost | Minimal | High (video + telemetry) |

| Outage resilience |

|

|

| Model updates | Mesh OTA, no downtime | Central, adds delay |

| Data sovereignty |

|

|

| Cybersecurity Built-in |

|

|

| Scalability |

|

|

| Deployment speed | < 1 hour | Days to weeks |

By contrasting local-first architecture with traditional cloud-dependent models, the advantages become clear: faster response, lower cost, and stronger resilience. For construction sites that demand real-time awareness and uninterrupted operations, MetaLynx ensures that safety, compliance, and asset intelligence remain active even in challenging conditions. Optional cloud connectivity can be layered on for cross-site reporting and orchestration, but the foundation remains local, secure, and self-sufficient.

Faster detection of PPE violations compared to manual monitoring.

Faster incident response with automated alerting on-site.

Super-fast event detection to actionable alert under typical conditions

Construction sites are increasingly connected environments, with cameras, sensors, mobile devices, and digital project management tools all feeding into day-to-day operations. This connectivity improves efficiency, but it also creates new vulnerabilities: ransomware, data theft, and AI-driven cyberattacks can halt projects and expose sensitive information. Smart Construction addresses these risks by embedding cybersecurity directly into the edge platform rather than relying on cloud defenses alone.

All data – whether video, telemetry, or RTLS location streams – is processed and stored locally within the VeeaHub mesh. This edge-local architecture ensures that sensitive workforce and operational data never has to leave the site, reducing exposure and simplifying compliance with privacy and data sovereignty requirements. Each VeeaHub enforces micro-segmented policies that isolate connected devices and applications, so even if a single endpoint is compromised, threats are contained before they can spread across the site.

The mesh network itself is encrypted end-to-end, with secure onboarding for cameras, IoT devices, and RTLS tags. Communications between hubs are protected against interception or tampering, while AI-driven intrusion detection continuously monitors for anomalies at the edge. By keeping intelligence and defenses on site, Smart Construction delivers resilient operations, strong data privacy, and a security posture designed for the realities of today’s evolving cyber threat landscape.

Smart Construction delivers measurable value by combining advanced edge computing with real-time AI analytics, enabling jobsites to operate more safely, efficiently, and securely. Traditional approaches often rely on fragmented systems or cloud-only architectures that introduce latency, create visibility gaps, and increase costs. By contrast, Smart Construction unifies safety monitoring, compliance enforcement, and asset intelligence into one cohesive platform that processes data locally at the edge. This ensures millisecond response times, continuous operation even in low-connectivity environments, and complete control over sensitive project information. The benefits extend beyond immediate safety outcomes—organizations also see lower operational risk, reduced insurance exposure, better equipment utilization, and data-driven insights that support more predictable project delivery and stronger financial performance.

Construction sites demand immediate action when safety or compliance issues arise. By processing all events locally at the edge, Smart Construction reduces reaction times from minutes to milliseconds. This ensures managers and supervisors can step in exactly when it matters—preventing injuries, enforcing safety rules, and reducing costly downtime without waiting on cloud roundtrips.

Jobsites produce highly sensitive data, including video footage, workforce telemetry, and operational metrics. Smart Construction ensures that this information never has to leave the site, significantly reducing exposure to cyber threats. With built-in AI-driven cybersecurity, the platform actively safeguards both data-at-rest and data-in-motion, providing strong protection against ransomware, intrusion, and data theft.

Safety and asset tracking often operate in silos, creating fragmented visibility. Smart Construction fuses computer vision, RTLS tracking, and policy management into one integrated platform. This unified approach provides superintendents and managers with a complete, real-time picture of the jobsite—who is on site, what equipment is in use, and where risks are emerging—all in a single pane of glass.

Construction projects evolve rapidly as layouts change, subcontractors rotate, and new equipment arrives. Smart Construction was designed to adapt effortlessly, using a mesh architecture that automatically expands as new hubs are added. Each additional node extends both compute capacity and visibility, ensuring that safety and compliance capabilities keep pace with the complexity of the jobsite.

Beyond safety, Smart Construction directly improves financial performance. By reducing rework, preventing asset loss, and automating compliance reporting, the platform lowers operational costs and insurance exposure. Real-time analytics further empower executives with verifiable insights into workforce productivity, asset utilization, and site efficiency—driving data-driven decisions that improve profitability and project outcomes.

Run Honeywell Niagara on VeeaHub as a containerized edge app, side-by-side with Smart Construction. You get one local platform for site systems and safety workflows, with data staying on-site and no dependency on WAN. Niagara handles the temporary infrastructure layer while MetaLynx handles vision, RTLS, and policies—so superintendents see facilities, people, and assets in one place.

To accelerate time to value and ensure construction teams can experience the benefits of Smart Construction without delay, Veea offers a pilot kit that delivers a fully operational deployment in less than one hour. This kit is designed to demonstrate the complete capability of the platform in a controlled, repeatable way: combining pre-configured VeeaHub edge nodes with the MetaLynx Smart Construction applications already provisioned for safety, compliance, and asset intelligence use cases.

From the moment the kit is powered on, managers gain immediate access to live dashboards, event-driven alerts, and the unified policy engine, validating how real-time insights at the edge transform safety and operations on site. By simplifying installation and eliminating complex integration steps, the pilot kit provides a rapid and low-risk path for organizations to move from proof-of-concept to scaled deployment across multiple projects.

VeeaONE™ with MetaLynx™ Smart Construction application suite

PPE compliance, restricted zones, collision avoidance, fire/gas detection, anomalies

OTA updates without downtime

Sub-50 ms for event detection to actionable alert under typical conditions

Specifications subject to change without notice. Country-specific regulatory information is available upon request.

Veea, Veea Logo, Veea Shield Logo, VeeaHub, vMesh and vTPN are registered trademarks of Veea Inc. Other trademarks and trade names are those of their respective owners. Arm and Cortex are trademarks or registered trademarks of Arm Limited (or its subsidiaries) in the US and/or elsewhere. The related technology may be protected by any or all of patents, copyrights, designs and trade secrets. The Bluetooth® word mark and logos are registered trademarks owned by Bluetooth SIG, Inc. Zigbee Alliance’s trademarks and logos, and all goodwill associated therewith, are the exclusive property of the Zigbee Alliance. Thread Group, Thread, Built on Thread and Thread Certified Component word marks and logos, are registered and/or unregistered trademarks and service marks of Thread Group in the United States and/or other jurisdictions. Wi-Fi is a registered trademark of Wi-Fi Alliance®. The SD, SDHC, miniSDHC, microSDHC, SDXC and microSDXC Logos are trademarks of SD-3C LLC. Docker and the Docker logo are trademarks or registered trademarks of Docker, Inc. in the United States and/or other countries. Docker, Inc. and other parties may also have trademark rights in other terms used herein.

© 2014 - 2026 Veea Inc. and its subsidiaries. All rights reserved.

Veea and VeeaHub are trademarks of Veea Inc. All other trademarks and trade names are the property of their respective owners.